The world of manufacturing is undergoing a revolutionary change. As manufacturers adopt smart technologies to meet rising demands for speed, precision, and data-informed decisions, there’s a renewed focus on the basics, especially in the realm of workholding.

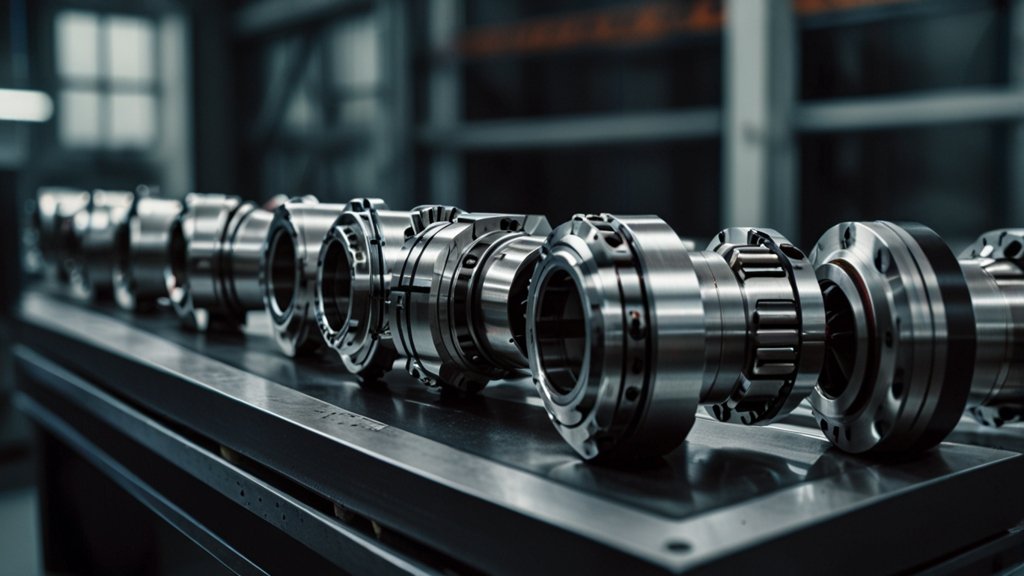

At the center of this shift is a once-unassuming component, now elevated to new levels of accuracy: the collet chuck.

It may not generate the buzz of robotics or AI, but this small device plays a crucial role in ensuring machined parts, often to micron-level precision, are held securely and repeatably. In connected factory setups, where even a slight misalignment can lead to cascading inefficiencies or part failure, high-precision workholding systems like these have become indispensable for advanced manufacturing processes.

But what is a collet chuck exactly? And why is it gaining renewed attention in today’s advanced machine shops? Let’s take a closer look.

What Is a Collet Chuck?

Before diving into modern relevance, let’s start with the basics.

A collet chuck is a type of chuck that uses a slotted cylindrical sleeve (the collet) to grip a tool or workpiece. It tightens concentrically by compressing into a tapered collar, ensuring a firm and precise hold. Unlike conventional three-jaw chucks that grip at separate points, this device grips around the entire circumference, reducing runout, improving centering, and supporting higher RPMs.

The result is a reliable, balanced grip that minimizes deflection and vibration during machining. Especially in automated and high-speed environments, this kind of workholding solution ensures both accuracy and consistency, time after time.

The Evolution of Workholding in the Industry 4.0 Era

Industry 4.0 has redefined priorities. Manufacturers now aim to hold components precisely and intelligently, not just firmly.

Traditional clamping methods introduced variables that automated systems couldn’t compensate for. Misaligned parts or uneven grip often resulted in downstream rejects or machine stoppages.

Modern workholding tools solve this through a blend of mechanical innovation and digital compatibility. Designed for seamless interaction with high-speed spindles, sensors, and CNC interfaces, advanced variants now offer:

● Real-time pressure monitoring

● Reduced vibration at high speeds

● Quick changeovers to reduce downtime

● Smart integration for predictive maintenance

Advanced holding systems ensure not just better part accuracy but also improved data collection and system feedback, forming the basis of agile, intelligent manufacturing lines.

Not All Collets Are Created Equal

With the push toward universal and flexible machining, understanding different toolholding types is essential. Here’s a look at the most common variants in use today:

ER Collets

Versatile and widely used across milling, drilling, and tapping. Ideal for light-to-medium duty with balanced performance. They offer solid repeatability and are easy to install, making them suitable for most machine shops.

5C Chucks

Popular in lathe operations for fast changeovers and high repeatability. Excellent for bar stock and cylindrical work. These are preferred in many turning applications due to their simplicity and compact size.

R8 Systems

Compact and straightforward, typically used in smaller milling setups. Often seen in knee mills and educational environments due to their cost-effectiveness and ease of use.

Hydraulic Expansion Holders

Preferred for ultra-high precision applications. These use hydraulic pressure for consistent clamping and vibration damping. Their internal fluid compensation provides extreme accuracy for demanding jobs.

Pneumatic Workholding Devices

Great for automated environments. They use air pressure for rapid clamping, perfect for speed-driven production floors. These are excellent choices for high-volume operations where speed and automation are key.

The choice depends on several factors: part geometry, speed, load, automation compatibility, and required precision. Selecting the right device can impact both short-term output and long-term tooling health.

Precision as a Productivity Multiplier

In high-mix, low-volume industries like aerospace, medical, and electronics, even small inconsistencies can add up quickly across batches or lines.

That’s where precision clamping solutions prove their worth. Low runout leads to:

● Even tool wear

● Tightly controlled geometries

● Fewer manual adjustments

● Better surface finishes

More importantly, consistent workholding reduces process variations, which in turn leads to fewer quality issues. A small improvement in chucking accuracy can translate into hours saved each week on recalibration and rework.

Ultimately, this translates to less waste, faster cycle times, and reduced downtime, a true productivity multiplier.

From Passive Holder to Data-Driven Asset

In smart factories, toolholders are no longer passive. Many now come with embedded tech that allows them to interact with machines in real time.

Some of the latest innovations include:

● Sensors to monitor clamping force

● Wireless diagnostics

● Alerts for thermal drift or impending failure

The ability to collect and transmit data from even a chuck opens doors to predictive maintenance and closed-loop manufacturing. This ensures your machining stays stable without the need for constant human oversight.

Such features allow the system to prevent damage, reduce maintenance costs, and ensure uninterrupted operation.

Perfect Companion to CNC Automation

In today’s CNC-driven workflows, high-performance chucks complement automated functions by:

● Enabling robotic tool changes

● Speeding up part swaps

● Minimizing manual handling

● Supporting lights-out production

Automation thrives on repeatability, and precision toolholders ensure each tool or workpiece is held identically every time. When programmed with zero-point systems, they also allow faster and error-free setup changes, keeping your spindles turning longer.

With the right setup, machines can run through the night with minimal supervision. This isn’t about replacing people, it’s about letting skilled staff focus on programming, quality checks, and innovation, not repetitive tasks.

Leaner Manufacturing Through Smarter Clamping

Smart manufacturing is not just about adopting flashy tech. It’s about optimizing resources: less rework, shorter setup times, and higher throughput.

Thanks to their compact designs and consistent gripping strength, precision clamping systems enable manufacturers to:

● Implement lean practices

● Reduce inspection requirements

● Keep machines running with minimal interruption

Modern chucks also reduce tool chatter and extend tool life, indirectly improving ROI over time. In lean-driven production cells, the time saved during setups alone can justify a high-quality chuck investment.

Over time, these efficiencies add up, giving businesses the agility to scale, compete, and evolve.

Global Reach, Local Support: Schunk India

Schunk, a global name in precision tooling, has brought its trusted performance to the heart of Asia through Schunk India.

Renowned for toolholding systems and advanced clamping solutions, Schunk India supports both large factories and mid-sized workshops. Their technology is built for today’s digitally connected floors, combining reliability, modularity, and smart integration.

Local support ensures shorter lead times, easier consultation, and smoother after-sales service. Whether upgrading existing setups or building new lines, Schunk India delivers scalable solutions with unmatched consistency.

From tool rooms to production lines, their systems deliver performance you can trust.

Conclusion: Small Tool, Massive Impact

In a world obsessed with AI, automation, and algorithms, it’s easy to overlook the fundamentals. But core components like the collet chuck remind us that precision begins at the very first point of contact, how a part is held.

So the next time someone asks, “What is a collet chuck?”, the answer isn’t just mechanical. It’s strategic. It’s lean. It’s a vital enabler of smart production.

As factories evolve, expect even smarter iterations of these tools, blending mechanical engineering with digital intelligence to keep industry turning, literally and figuratively. Their contribution, though subtle, will remain central to the success of next-gen manufacturing.