In today’s fast-moving world, the need is greater than ever for fast, reliable diagnostic solutions. Rapid diagnostic tests, and especially lateral flow assays, have become a useful asset in countless various industries—ranging from pharmaceuticals and healthcare to food safety and environmental monitoring. But behind the sorcery of these small but potent diagnostic devices is an essential and precise manufacturing process. At its core lies a device called the lateral flow strip cutter.

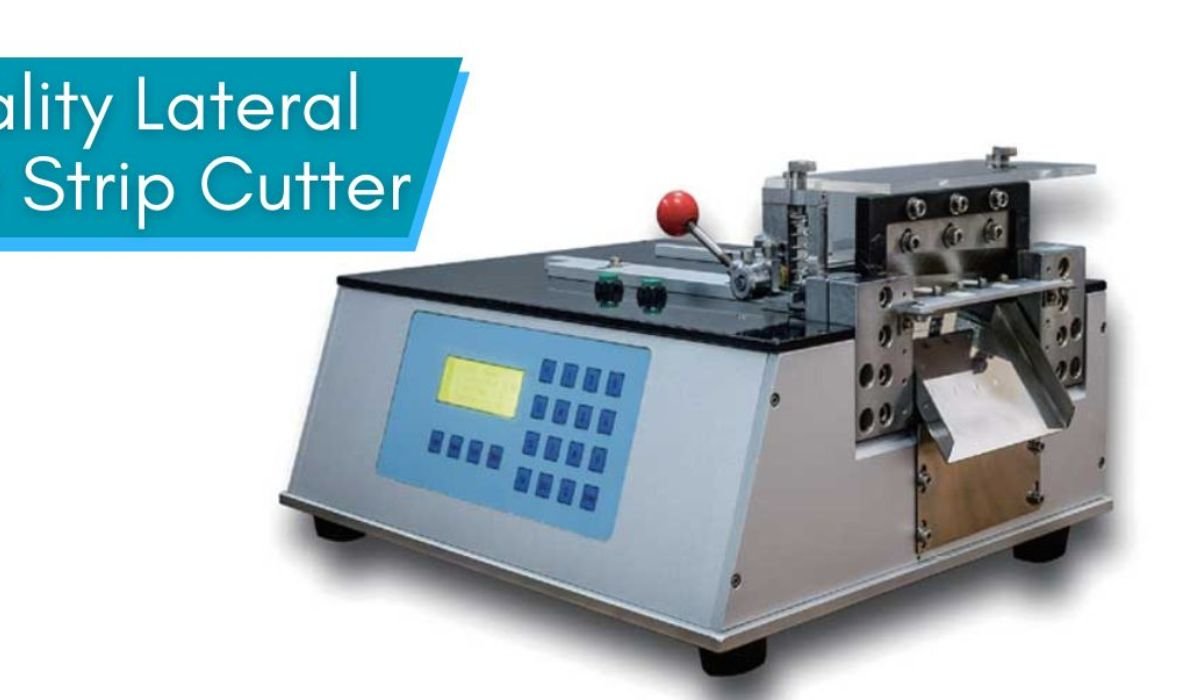

For every manufacturer engaged in the manufacture of lateral flow assays, having a good quality lateral flow strip cutter is no longer a choice but a mere necessity. It is the key to the provision of precision, consistency, and performance in manufacturing.

The Role of Lateral Flow Assays in Modern Diagnostics

Lateral flow assays (LFAs) are paper-based diagnostic platforms utilized to determine or detect the presence or absence of a target analyte in a sample. LFAs are well-known for being simple, portable, and quick. Pregnancy testing and infectious disease diagnosis, drug testing and food allergen screening, to mention a few, have all made it simpler and quicker to diagnose through the application of LFAs.

But although these tests look easy to apply, their manufacture requires extremely careful procedures. Precision of the test relies to a great extent on the assembly and alignment of each component—i.e., sample pad, conjugate pad, nitrocellulose membrane, and absorbent pad. Cutting the assembled sheet of test strips is one of the last but most important steps among them. That’s where the lateral flow strip cutter proves useful.

What is a Lateral Flow Strip Cutter?

A lateral flow strip cutter is a machine that is applied to cut large, laminated sheets of lateral flow material into individual strips. The strips are packaged in plastic cases or as dipsticks for application in testing. The cutter will provide each strip with accurate dimensions, smooth edges, and intact membranes.

There are different models of strip cutters, ranging from hand and semi-automated machines to automated equipment for bulk production. Regardless of the scope or range of business, the basic job is the same: precise and clean cutting of assay cards into neat, straight test strips.

Why Precision is Important in Strip Cutting

Precision in the production of rapid tests is not a courtesy–it is a necessity. Inaccurate edge or width of a test strip can result in substandard results. A strip slightly too wide can fail to seat well in its case, and a strip too narrow may cut into fluid flow required for proper test development.

A quality lateral flow strip cutter guarantees:

- Reproducible strip width per unit

- Uniform membrane and pad alignment

- Clean, snag-free edges that seal properly

- Lower waste and greater material yield

Accuracy of this sort contributes directly to the diagnostic result’s dependability. For the manufacturer, retaining such a level is essential to product quality and regulatory compliance.

Important Benefits of Using a Quality Lateral Flow Strip Cutter

A great investment in a lateral flow strip cutter is rewarding in various ways:

1. Better Product Quality

The uniform size and sharp tips of a good cutter minimize the possibilities of test failure. Besides enhancing the users’ experience, trust in your product is also portrayed through it.

2. Enhanced Manufacturing Efficiency

The presence of a reliable strip cutter enables more test cards to be cut within a unit of time by manufacturers. Automation features provide zero-operator high-speed cutting, a feature paramount when production is maximized.

3. Waste Minimization

Bungling or hand cutting can render strips unusable because of uneven edges or membrane damage. A high-quality cutter gives maximum usable product from the master card at the lowest material cost and wastage.

4. Flexibility and Customization

Most new strip cutters are adjustable to the width of cutting to handle various test formats. Manufacturers of various lateral flow assays need this flexibility to prepare various tests.

5. Regulatory Compliance

Production consistency is essential to passing regulatory standards. A lateral flow strip cutter ensures that your test strips are consistent to dimension tolerances, something of concern during product approval and validation.

Selecting the Correct Cutter for Your Application

Choosing the correct lateral flow strip cutter is subject to multiple considerations. Initially, the production size of the producers must be determined. For small labs or for start-ups, a manual or semi-automatic strip cutter can be used. But for big-scale production for global demand, an automatic strip cutter with high-tech features is the most appropriate choice.

The following choices require consideration in the selection of a strip cutter:

- Adjustable widths

- Easy to replace high-precision blades

- Minimum maintenance requirement

- All types of membranes, and card thickness compatibility

- Ease of use through interface or automation support

You also need to look for a supplier who can provide after-sales assistance, training, and spares. The cutter may be a long-term investment on your manufacturing line.

Impact on Rapid Test Manufacturing in Real World

Imagine a diagnostic company producing 100,000 lateral flow tests weekly. Without a reliable strip cutter, even a 1 percent faulty strip rate means 1,000 faulty tests. False positives or negatives can lead not only to a loss of faith but real health risks to consumers.

A properly designed lateral flow strip cutter obviates this margin of error. It will ensure that all tests shipped off the production floor perform as intended. With demand for quick tests still going strong around the world—particularly during periods of public health crises—companies must arm themselves with machines that will ensure speed and accuracy.

Looking Ahead: Innovation and Demand

As technological advancements in diagnostic technology increase, so do expectations of performance and reliability. Therefore, more new materials, multi-analyte test strips, and sophisticated detection means are being incorporated into lateral flow devices. To provide this new function, equipment to manufacture is more crucial, such as the lateral flow strip cutter.

More and more manufacturers are coming to find cutters that are able to keep pace with such innovations, whether it is cutting thinner membranes, two-lane test strips, or integrating with other stages of automated assembly lines. An ability to adapt with these trends will make or break a manufacturer’s competitive edge in a rapidly evolving industry.

Final Thoughts: Investment in Quality for Future Success

The lateral flow strip cutter itself is but a single component of a very sophisticated assembly line, yet its function is critical. A badly cut test strip will destroy the operation of a well-designed assay otherwise. Alternatively, accuracy-cut strips upgrade product quality in general, providing accuracy, reliability, and reproducibility.

To each manufacturer of quick tests, the selection of a proper lateral flow strip cutter is not a technical choice—it’s a business strategy. As the need for rapid and precise diagnostics goes up, so does the value in investing in quality equipment that enables scalable, precise production.

Ultimately, a quality cutter does more than simply cut strips—it forges your reputation, gets more efficient, and sets your brand up for long-term success in the competitive diagnostic industry.