In the world of electronics manufacturing, Surface Mount Technology (SMT) plays a critical role in producing compact, high-performance circuit boards that power everything from smartphones to industrial machines. Understanding SMT’s meaning, process, and advantages is essential for making informed decisions — especially when selecting a PCBA manufacturer to bring your designs to life. In this guide, we’ll break down SMT basics and provide practical tips for finding a reliable manufacturing partner.

What is SMT (Surface Mount Technology)?

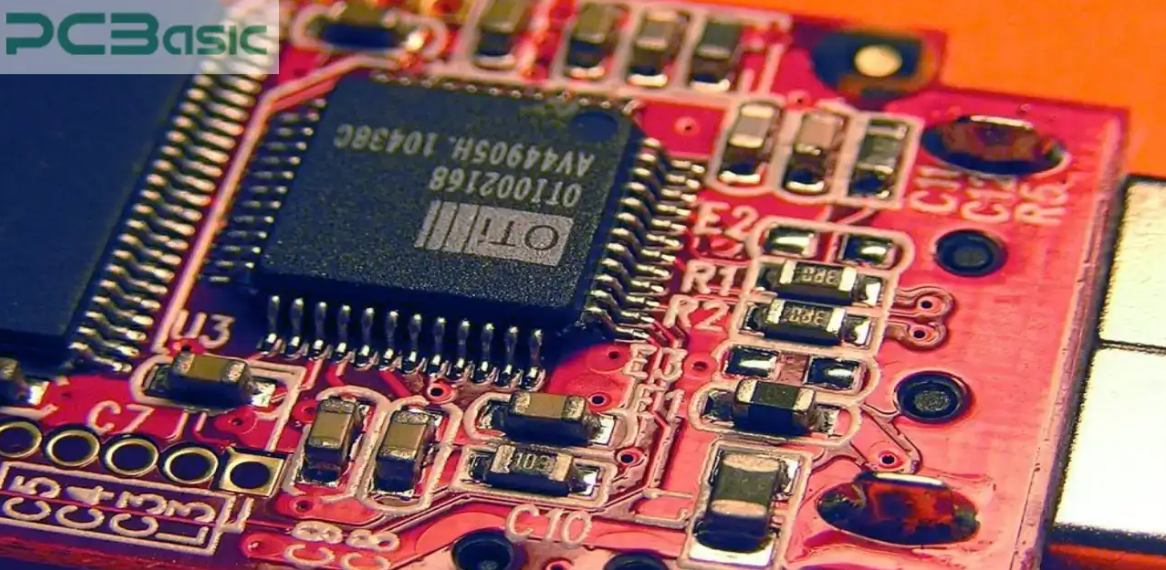

Surface Mount Technology (SMT) is a method of assembling electronic circuits where components are mounted directly onto the surface of printed circuit boards (PCBs). This technique contrasts with through-hole technology, where leads are inserted into drilled holes.

Key Features of SMT:

- Smaller components: SMT allows for tiny, lightweight parts that enable compact board designs.

- Higher component density: More components can be placed on both sides of the PCB.

- Automated assembly: SMT is compatible with high-speed pick-and-place machines, improving efficiency.

- Cost-effective for volume production: Reduced manual labor and faster production cycles lower costs.

Common SMT Components:

- Resistors, capacitors, and inductors

- Integrated circuits (ICs)

- Diodes and LEDs

- Transistors

SMT Process Overview

A typical SMT assembly process includes:

Solder Paste Printing

Solder paste is applied to PCB pads using a stencil printer.

Component Placement

Automated pick-and-place machines position components precisely on the board.

Reflow Soldering

The board passes through a reflow oven where solder paste melts and forms solid joints.

Inspection and Testing

Technologies like AOI (Automated Optical Inspection) and X-ray ensure solder quality and detect defects.

Why SMT Matters When Choosing a PCBA Manufacturer

When selecting a PCBA manufacturer, it’s important to evaluate their SMT capabilities because:

- Precision matters: Poor SMT assembly can lead to defects like solder bridges, tombstoning, or cold joints.

- Production flexibility: A good manufacturer should handle both prototype runs and mass production.

- Advanced equipment: Look for modern SMT lines with high-speed placement machines, reflow ovens, and in-line inspection systems.

How to Find the Best PCBA Manufacturer for Your Needs

Here are key factors to consider when choosing a PCBA manufacturer:

🔹 Technical expertise

Ensure the manufacturer has experience with SMT assembly and can handle complex board designs.

🔹 Quality standards

Check for certifications like ISO 9001, IATF 16949, or IPC-A-610 compliance to guarantee reliable manufacturing.

🔹 Equipment and capacity

Verify that they use advanced SMT equipment suitable for your board complexity and volume.

🔹 Prototyping and support

A reliable PCBA partner will assist from prototype to mass production, offering design-for-manufacturing (DFM) advice.

🔹 Lead time and logistics

Consider turnaround time and shipping capabilities, especially if you require fast delivery.

Conclusion

SMT is the foundation of modern PCBA manufacturing, enabling the production of high-density, high-reliability circuit boards. To achieve optimal results for your electronics projects, choose a PCBA manufacturer with strong SMT capabilities, proven quality systems, and responsive support. A trusted partner will not only assemble your boards but also help you enhance product performance and market competitiveness.

YOU MAY ALSO LIKE: The Importance of True RMS Average Power Sensors in Accurate Power Measurement